Expansion Joint for flue gas

A universal spent catalyst standpipe expansion joint is installed in a FCCU (Fluid Catalytic Cracking Unit) at Lukoil in Russia.

Operating conditions: p = 3.79 barg (55 PSIG); t = 538 °C (1,000 °F); d = 1,060 mm (42"). Medium: flue gas.

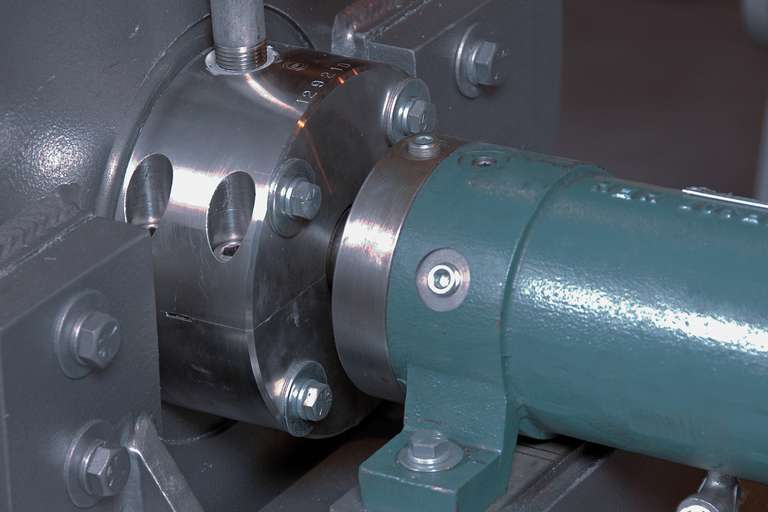

Reliable dual seal for hydrocarbons

Since 2002, an EagleBurgmann H74F-D dual seal - supplied by a system according to API 682 Plan 32 + 53B has been running in a Worthington pump at the refinery in Salamanca, Guanajuato, Mexico.

Operating conditions: p = 19.29 bar (280 PSI); t = 251.67 °C (485 °F); n = 3,500 min-1; d1 = 50 mm (1.97"). Media: hydrocarbons.

Dual mechanical seals used in pumps of a catalytic cracking unit

EagleBurgmann LL9DTUU dual mechanical seals are applied to seal a Sulzer pump of a catalytic cracking unit operated by Chennai Petroleum Corporation Ltd. in India.

Operating conditions: p = 13.73 bar (199 PSI); t = 40 °C (104 °F); n = 2,965 min-1; d1 = 70 mm (2.7"). Media: hydrocarbons.

Large size and safe expansion joint

EagleBurgmann provided a large sized universal spent catalyst standpipe expansion joint for a refinery in Texas, USA.

Operating conditions: p = 3.79 barg (55 PSIG); t = 732 °C (1,350 °F); d = 1,500 mm (59"). Media: flue gas and catalyst fines.

Reliable dual seal in 63 pumps

The catalytic cracking unit of Tüpras Izmir Refinery, Turkey was commissioned in 2001. EagleBurgmann type H75 dual seals with supply systems according to API 682 Plan 11 + 52 + 61 are successfully sealing the shafts of 63 pumps in this unit. 18 of these pumps have never had to be shut down for maintenance of the mechanical seals.

Operating conditions: p = 2.71 bar (39 PSI); t = 101 °C (214 °F); n = 2,955 min-1; d1 = 50 mm (1.97"). Media: hydrocarbons.

Hydrocarbons reliably sealed

The shafts of KEPL pumps of Chennai Petroleum Corporation Ltd. in India are reliably sealed by EagleBurgmann metal bellows seals type MFLWT80/90 and MFL65F/85.

Operating conditions: p = 16.08 ... 19.93 bar (233 289 PSI); t = 238 °C ... 263 °C (460 °F 505 °F); n = 2,955 min-1; d1 = 80 mm (3.15"). Media: hydrocarbons.

Securely sealed hydrocracker unit with high pressure seals

A high pressure EagleBurgmann type PDGS2.1/130 dry gas seal seals a Bhel compressor in the hydrocracker unit of the Panipat refinery in India.

Operating conditions: p = 179 bar (2596 PSI); t = 160 °C (320 °F); d1 = 112 mm (4.41"). Media: H2 + CH4, N2.

Long life mechanical seals for between bearings pump

Since 2001, PDVSA (Petroleos de Venezuela) has been using EagleBurgmann seals type H75K/110 with supply system TS6050 according to API 682 Plan 52 in a Sulzer between bearings pump.

Operating conditions: p = 4 bar (58 PSI); t = 52 °C (126 °F); n = 3,560 min-1; d1 = 80 mm (3.15"). Media: aromatic hydrocarbons.

On-site meet on-time

During T&I 2013 all heat exchangers in a German refinery have been equipped with low emission graphite gaskets Statotherm 9593/HDR Pro from EagleBurgmann. The gaskets have been manufactured in the EagleBurgmann service center located on-site and have significantly contributed to meet on-time repair schedules.

Successful sealed compressor in cracking unit

In a cracking unit in the United States a compressor is sealed by EagleBurgmann Espey carbon floating ring seals type WD200 and WDKS.

Operating conditions: p = 5 bar (73 PSI); t = 75 °C (167 °F); n = 3,000 min-1; d1 = 55 mm (2.17"). Medium: cracked process gas (containing dust).

Hermetically sealed multistage vertical pump

EagleBurgmann has designed a new high performance type NMB 22P-10R-65-ND2 magnetic coupling. This is installed in a multistage vertical can pump of an ethylene cracker unit in a German refinery.

p = 65 bar (943 PSI); t = -32 ... +40 °C (-26 °F ... +104 °F); n = 2,980 min-1; drive power: 315 kW direct start; design torque: >1,700 Nm. Media: hydrocarbons C2 + C4.

Heavy crude oil secure sealed with metal bellow seals

Type MFL65-D1/130 face-to-face dual stationary seal with supply system to API 682 Plan 54, installed in a crude oil pump in the thermal cracking unit at Conoco Humber Refinery (England).

Operating conditions: p = 13.4 bar (194 PSI); t = 400 °C (752 °F); n = 3,500 min-1; d1 = 111 mm (4.37"). Medium: heavy crude oil.

Read the complete case study...